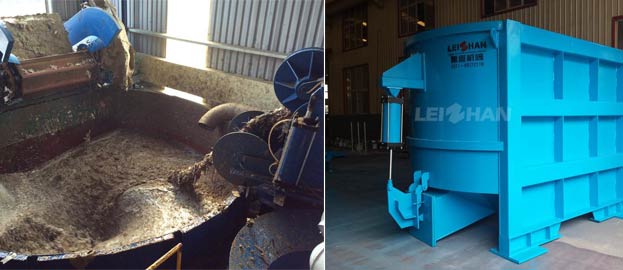

In paper making process, the slime pulp will be produced frequently. If we don’t clean these slime on time, as time passes, will influence the paper making efficiency and pulp quality.

1. Checking and washing the system to remove the slime and related pulp;

2. Checking bend, dead angle of pulp pipe and clean;

3. Checking the dispersion state of chemical addition agent and the mixing state of join point;

4. Open and clean spray pulp pipe in headbox;

5. Clean and report the dead angle of headbox and take correct measures;

6. Evacuation and washing headbox to eliminate excess foam;

7. Checking inner sizing condition, if need, increasing the usage of defoamer;

8. Clean horizontal vacuum box every weekend;

9. Checking the felt vacuum box and ensure it’s clean;

10. Checking sizing press starch boiling system;

If there are excess slime appeared, it’s necessary to get a system clean. These are the part of solutions about dealing methods of slime pulp, if you met other problems in paper making, welcome to consult us. Email: leizhanchina@gmail.com

If you have any requirements or questions, please leave a message, we will reply you as soon as possible!